200

Text on 3D Component Surfaces

Tools used in this Demo – 1/8” and ¼” Ball Nose

Create Design

- Start new file – Fill out job set up

- Single sided

- 11 W x 3.5H x 0.75 Thick

- Choose data point preferences

- Click OK

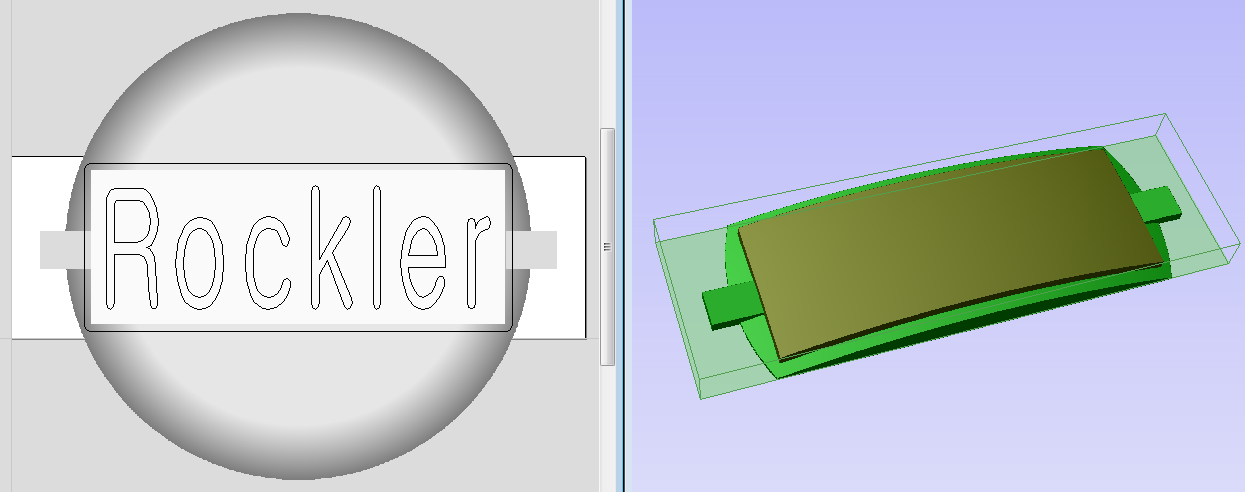

- Go to Clip Art Tab

- Go to “Domes” folder

- Select “Dish_Dome_30”, double click will center it

- Go to “3D Tabs” folder

- Select “Rectangular_0.5”, double click will center it

- Select “Rectangular_0.25” and drag one to line up with left of the work piece

- Go to drawing tab to resize all 3D Objects

- Select the Dome

- Select “Set Selected Object Size”

- Enter 9” in either width or height and check box to link XY

- Click Apply and Close

- Select the Rectangular 0.5” Object

- Select “Set Selected Object Size”

- Enter 8” W x 3” H

- Click Apply and Close

- Select the Rectangular 0.25 Object

- Select “Set Selected Object Size”

- Enter 1” W x 0.75” H

- Click Apply and Close

- Adjust height and relationship between all 3D Objects

- Go to Modeling Tab

- Select the Dome by double clicking to bring up the properties box

- Change Height to 0.5”

- Change Base Height to 1/16”

- Check “Add”

- Click Close

- Select the Rectangular Object by double clicking to bring up the properties box

- Change Height to 3/16”

- Check “Add”

- Click Close

- Locate first 3D tab, got to properties and change to 3/8” thick, locate on left side then copy to the right side

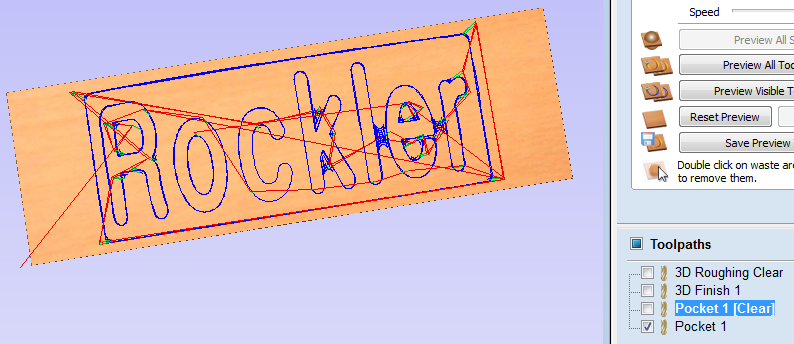

- Create Text Box

- Go to Modeling Tab

- Select Rectangular _0.5

- In 3D Model Tools, select “Create Vector Boundary”

- Go to Drawing Tab

- Select the boundary box created in step above

- Select “Draw Text in Vector Box”

- Enter “Rockler”

- Chose Text “Gulim”

- Check Bold

- Check Normal Margin

- Vertical stretch set to “Stretch Characters”

- Click “Close”

- Select “Edit text spacing” and add spaces between letters to allow for an 1/4” EM tool

- IMPORTANT Select Box and create an offset of 1/8”, delete original, TJ to explain this

- You should have something like the above picture and are now ready to make TOOL PATHS

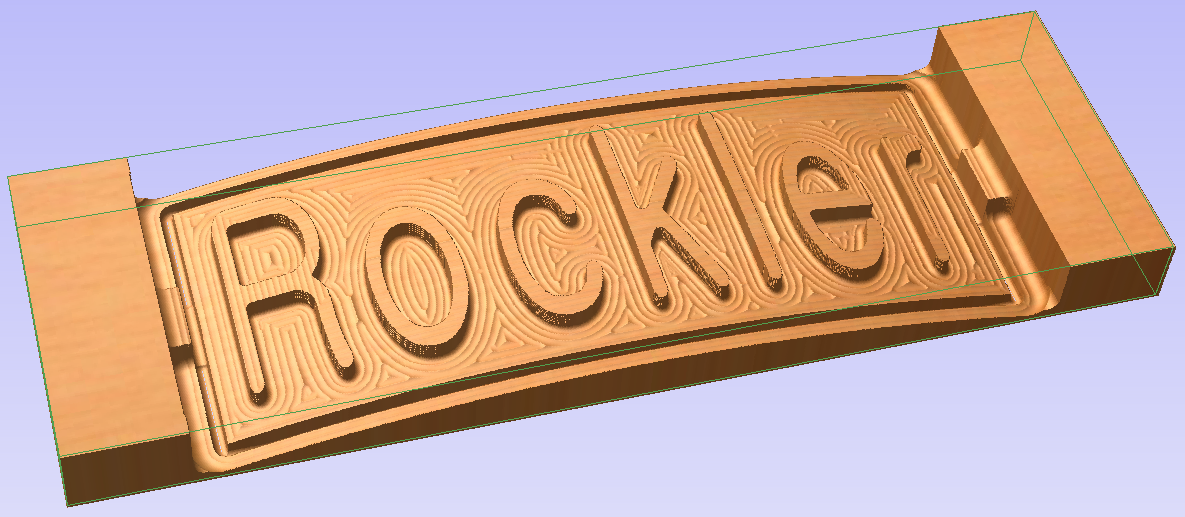

Create TOOL PATHS

Set properties

Set properties

- Tool clearance to 1”

- Set datum to lower left

- Use 3D Roughing tool path

- Select the border box

- Select 3D Roughing tool path

- Select 1/4” Ball Nose and enter depths and speeds for your machine

- Check “Selected Vectors”

- Enter a boundary offset of 0.25”

- Enter a machine allowance of 1/32”

- Select Z Level, Raster X, Profile None

- Change Name to Roughing Clear

- Click Calculate

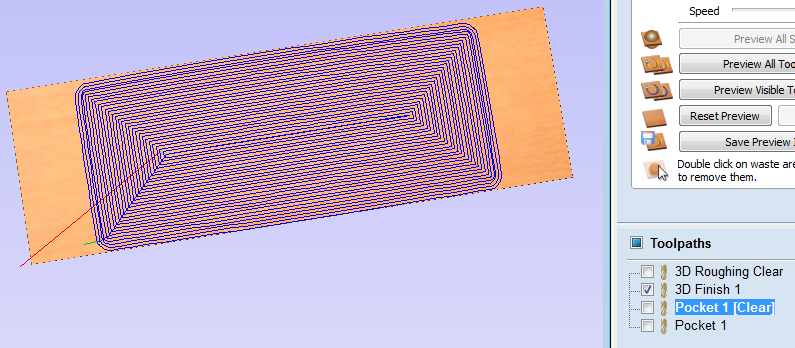

- Use 3D Finishing tool path

- Select the border box

- Select 3D Finishing tool path

Select 1/4” Ball Nose and enter depths and speeds for your machine (to make a nice smooth finish on the top of the letters, either use a small step over number or sand smooth when done)

Select 1/4” Ball Nose and enter depths and speeds for your machine (to make a nice smooth finish on the top of the letters, either use a small step over number or sand smooth when done)- Check “Selected Vectors”

- Enter a boundary offset of 0.125”

- Select Offset Conventional

- Change Name to Finish Surface

- Click Calculate

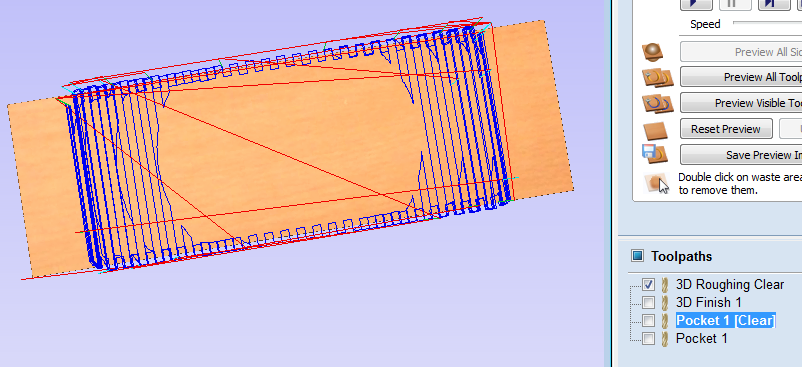

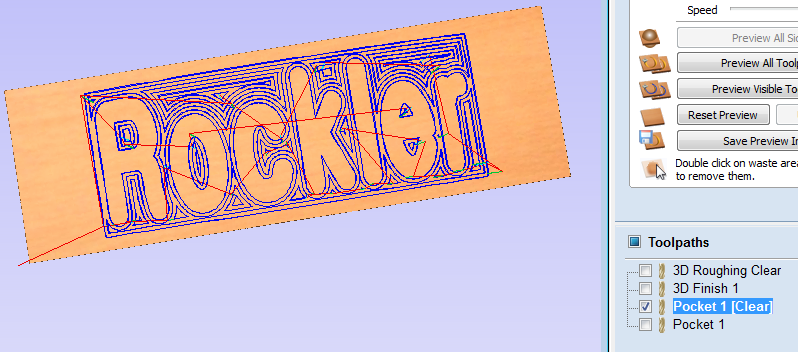

Use the “Pocket” tool path

Use the “Pocket” tool path

- Select both the text and border box

- Select Pocket tool path

- Set start depth to 0”

- Set cut depth to 3/16”

- Check “show advanced toolpath options”

- Select 1/8” Ball Nose and enter depths and speeds for your machine

- Check “Use Larger Area Clearance Tool”

- Select 1/4” Ball Nose and enter depth and speeds for your machine

- Select offset / conventional

- VERY IMPORTANT Click box for “Project toolpath onto 3D model”

- Change name to Pocket Text

- Click Calculate

- You will notice 2 toolpaths were made, one for each tool size

Save above Tool Paths to USB drive

Save above Tool Paths to USB drive

- Add tool description to file name, for pendant machines make first 5 characters meaningful

- Save ENTIRE project file

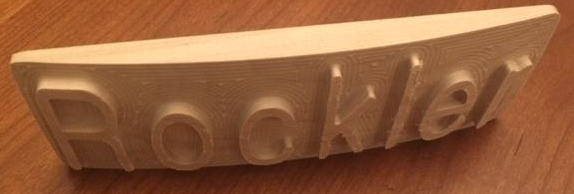

- DONE – ready to cut

Set up wood to be cut

- Make sure properly secured

- JOG create 0,0,0

- Run file for 3D Rough (pre run before Demo)

- Run file for 3D Finish (pre run before Demo)

- Run file for Text Pocket Clear

- Run file for Text Pocket

Question?

Ideas for next Demo…