Message from the President

Just a quick note from me this month. I have to apologize for not making it to the February Meeting. I was planning to be there. but I had a fall and broke my ankle and was at Urgent Care. I have been recuperating under the excellent care of my wife and should be there in March. Thank you for all the calls and texts wishing a speedy recovery. Thank you to Rick Reimer for filling in running the meeting with only a moment’s notice.

Keep up the great work making toys. With your help we are sure to break records this year. I look forward to seeing you all very soon and don’t forget to bring your latest projects for show-and-tell to the March woodworker’s meeting. See ya there.

Treasurer’s Report

Club treasurer Phyllis Minert presented the treasurer’s report. All transactions have been reconciled. Phyllis also noted that the club has a savings account (with $250).

Club Business

Chuck Petrovich is a member of an online woodworking club. An individual posed this question: the person has a CNC machine that he uses 6 days/week for work and was asking if he should rent the machine on Sundays to generate additional revenue, and if so, what should be the rental fee? Chuck shared his opinion: “bad idea”, which garnered several replies. Your thoughts?

SkillsUSA held their California Regional Woodworking competitions on Saturday, February 10. There were sufficient industry partners to serve as proctors and judges, so Inland Woodworkers support was not required. We heard that the competition went well, albeit somewhat chaotic due to the online nature of the contest. There was only 1 proctor in each classroom, so the camera feed was insufficient to monitor each of the students simultaneously. Some of the students assisted by streaming feeds from their own phones. This was the first attempt at a hybrid competition where the monitors and judges were online and the proctors and students were in the school woodshops. Some adjustments might be needed for next year.

Upcoming: The SkillsUSA California State competitions will occur on Saturday, April 6 at Chaffey High School. Volunteers are asked to arrive at 7am. The competition will begin at 8am. Classroom setup will take place on April 5, starting at noon. Help might be required. More details will be provided at the March IW meeting.

501 (c)3 status – no updates, still waiting on an accountant.

Show & Tell

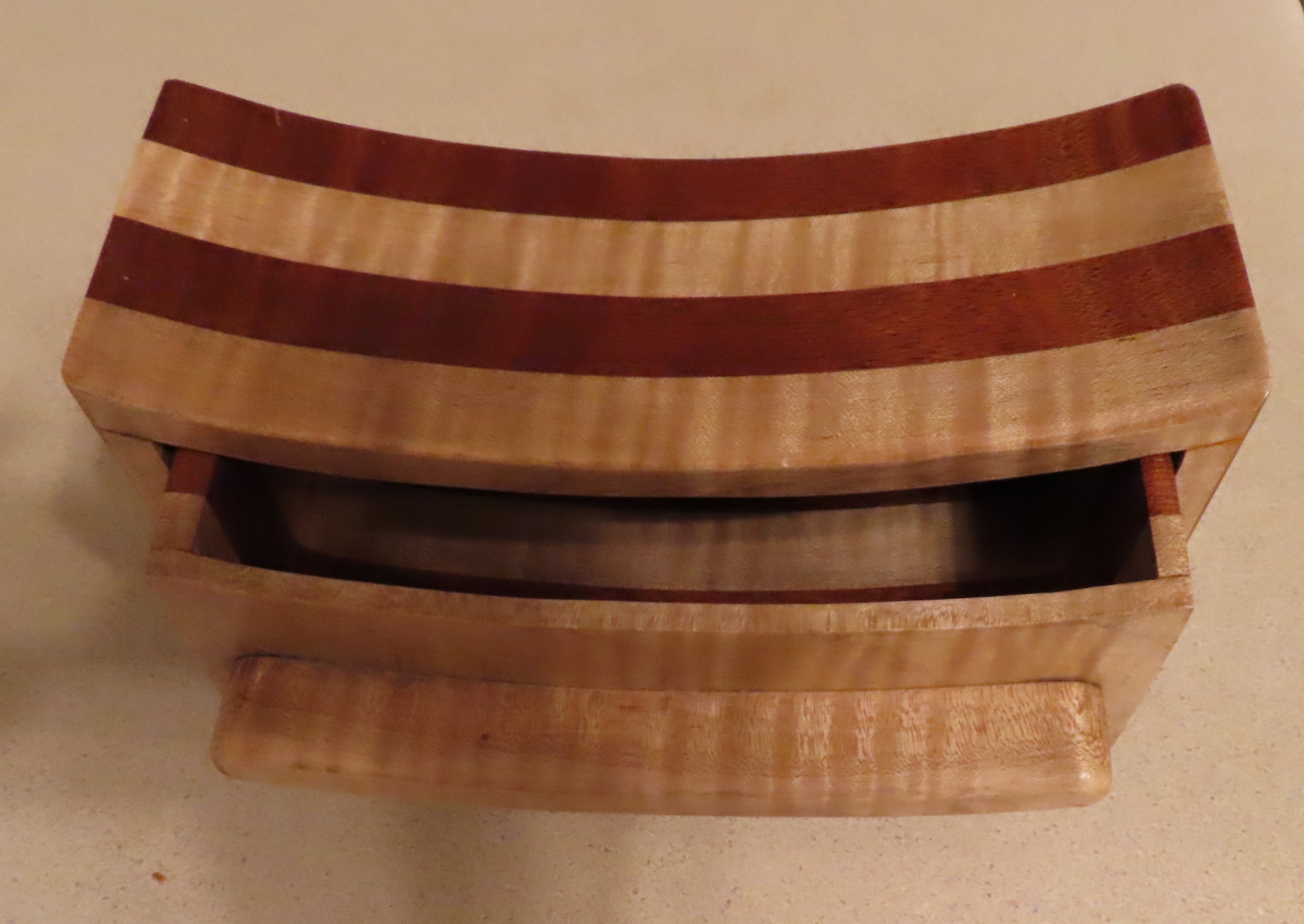

RJ Monsma made a bandsaw box using his scrollsaw. Why? To prove that it could be done! And at the time, he didn’t own a bandsaw. The box was made from mahogany and maple.

Michael Mark made a box with square dovetails and a keepsake box that he gave his wife for Christmas. The box has a puzzle on top, and the puzzle parts are held by magnets. The box was made from cedar wood.

He also made a wooden tongue drum. He explained is method for tuning the keys as follows: cut each key close to the design, then remove wood from the underside of each key to tune it. Remove wood from the front to raise the note and from the back to lower the note. He also noted that the selection of lumber for the top surface is crucial – use a hard wood with good reverberation. The drumsticks are made from super balls attached to dowels.

Michael also made some toy spinners (hand tops) that he will be donating to the 2024 annual toy drive.

Ernie Gonzalez shared a plaque that he has been working on.

Presentations

The Inland Woodworkers welcomed Ben Angerer, west coast regional manager for Shaper Tools (www.shapertools.com). Ben is a woodworker from Germany who went through formal training at the Guild. He worked at Festool for 10 years before joining the Shaper team.

The objective of the Shaper Origin Routing System is to make routing simple and accessible to everyone. Traditional CNC machines require space, a considerable financial investment, and a big learning curve, which in some cases, requires a working knowledge of machining G-codes. Instead, the Origin simplifies the user experience by incorporating algorithms to determine its position on the material, coupled with domino-style markers to index its position.

The user interfaces with the Origin using a simple graphical interface, which provides several options. The user can import pre-programmed files and design files (e.g., SVG files), or can create a design right on the machine. And there are no restrictions on project size.

Ben gave a demonstration of creating a circle and routing the part. First, he selected a circle from the option list. Then, he set the center and radius. Next, he selected the machining path (cut along the diameter, inside of the diameter, or outside of the diameter). Lastly, he set the depth of the cut. Very simple! Now it was time to cut. Club Secretary Michael Miller volunteered to run the machine. All that was needed was to move the router to align with the arrows on the screen, and the machine did the rest!

The Shaper has a 1-inch swing left and right of center, so as the operator moves the router, the Shaper positions itself exactly along the cut line. If the operator exceeds the cut line by more than 1 inch, the Shaper will retract the bit and flash a warning on the screen. The operator merely repositions the machine above the cut line and continues machining.

The Shaper is a simplified approach to CNC routing. It is very useful for prototyping and single-part cutting. It has attachments for dust collection and uses standard collets. It also has a Wi-Fi interface that can be used for transferring files to the machine.

Thank you Ben for this great presentation.

As always, thank you Sundowners for hosting our monthly meeting.