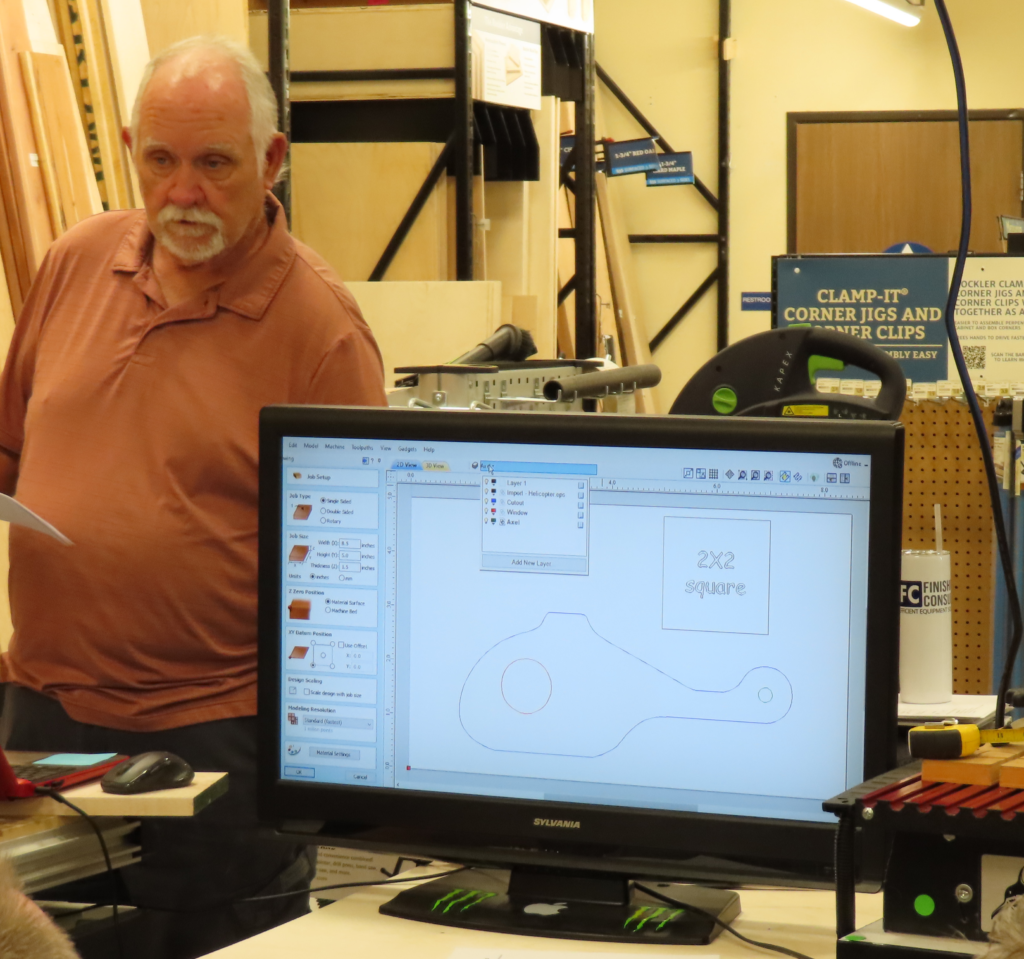

Its summer, and that means time for barbecuing, picnicking, and CNC routing! This month’s topic was Tips & Tricks, led by Rick Reimer. There were 12 members in attendance. A technical glitch caused a slight delay, but with the expertise of club members, the issue was quickly resolved and the training began.

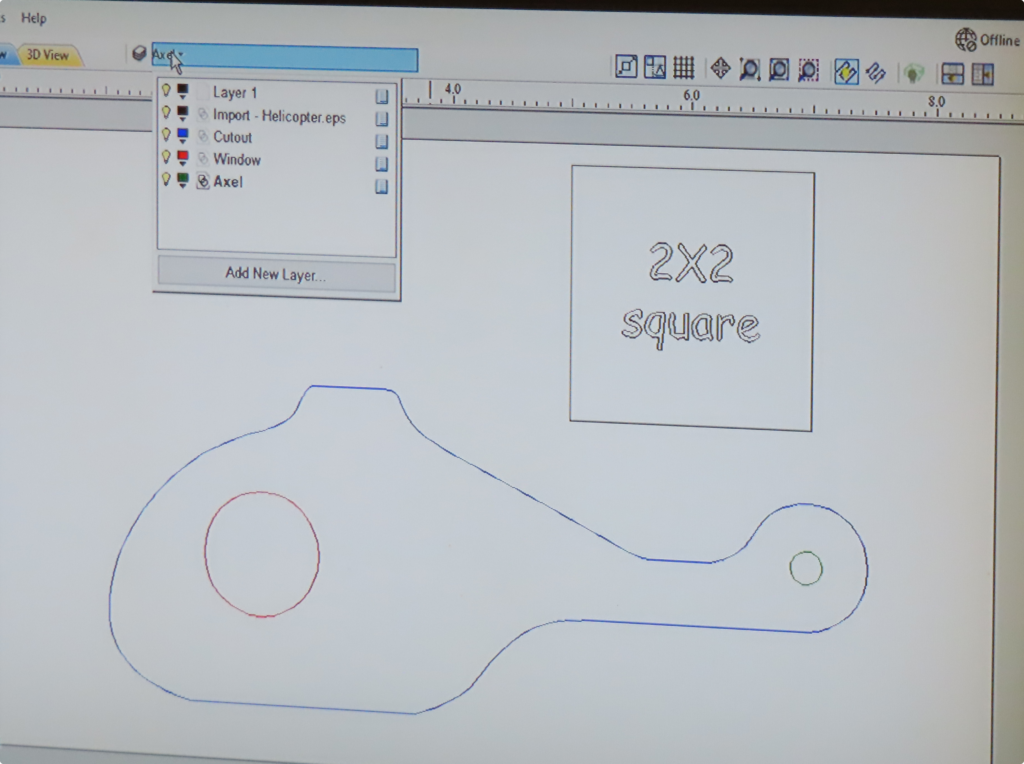

Rick used a toy helicopter design as the basis for today’s discussion.

Rick used a toy helicopter design as the basis for today’s discussion.

His first trick: use an identifier to set the scaling. In this case, the 2×2 square. This will allow you to resize your project and set the appropriate dimensions on your machine. This will be handy if you receive a design from someone else.

Rick recommends putting the scaling indicator on a separate layer. He also suggests using separate layers for the individual components.

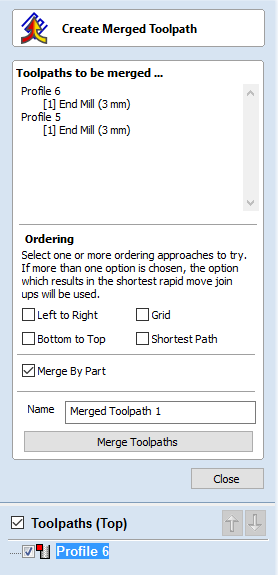

Rick also reviewed tool path creation and tool ramping. After that, we discussed the benefits of making multiple copies with parts nesting. Vectric can optimize the layout when cutting multiple versions of the same project.

And for those with Desktop Pro, Vectric can merge the toolpaths into one file.

With the design complete and tool paths defined, it was time to make some parts! The file was transferred to the Shark CNC Machine at the Rockler Ontario store, and the cutting commenced.

Reminder: due to the Labor Day holiday, the September meeting has been moved to Saturday, September 9th.