It was the fourth day of a triple-digit heatwave – a perfect time to relax in the air conditioned Rockler Ontario store and learn about CNC machining! 10 woodworkers joined with instructor TJ Imholte to learn about cutting stacked text. Welcome to new member Scott Jepson, who recently purchased a Genmitsu 4040 Reno Desktop CNC router.

TJ began the lesson with a comparison between inlay text and carved text. The topic then branched into a detailed discussion, including his recommendations for inlay work: use soft maple, cherry, walnut, and purpleheart for the best results. Oak is too fibrous for inlays, and teak requires epoxy for the glue-in. Others suggested alder. The group then discussed machining speeds and feeds, and TJ noted that bit vendors tend to publish values optimized for larger production machines. He suggested starting with 50% of those values for the travel speeds.

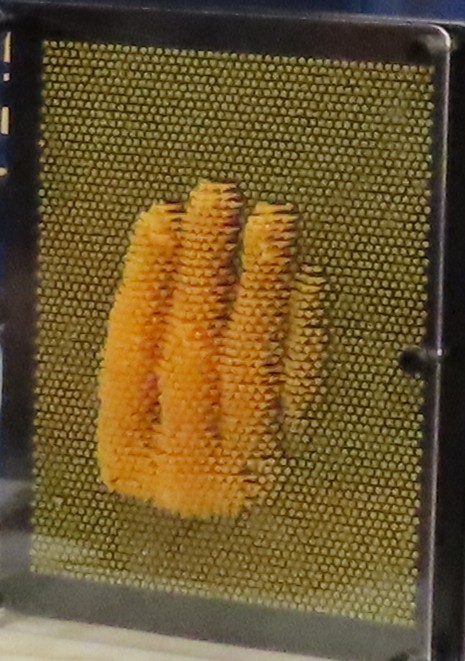

TJ next explained the concepts of pixels and pixelation and gave an excellent demonstration using a profile tool:

He then transitioned into the day’s topic, which was stacked text. This topic has been discussed at prior training session, but worthy of an update using the latest version of Vectric. However, before he could proceed, TJ was rudely interrupted by a minor earthquake. And then another. Being the professional that he is, TJ paused for the shake, smiled, and continued with the lesson.

Some of the training highlights: put each text field on its own layer. Create a Merge layer independent of the other layers, then copy both text fields to the merge layer. Changes in one layer do not transfer to the other layers; modifications in the merge layer do not impact the original text layers. So, if the merge layer is wrong, erase everything and recopy the original text layers.

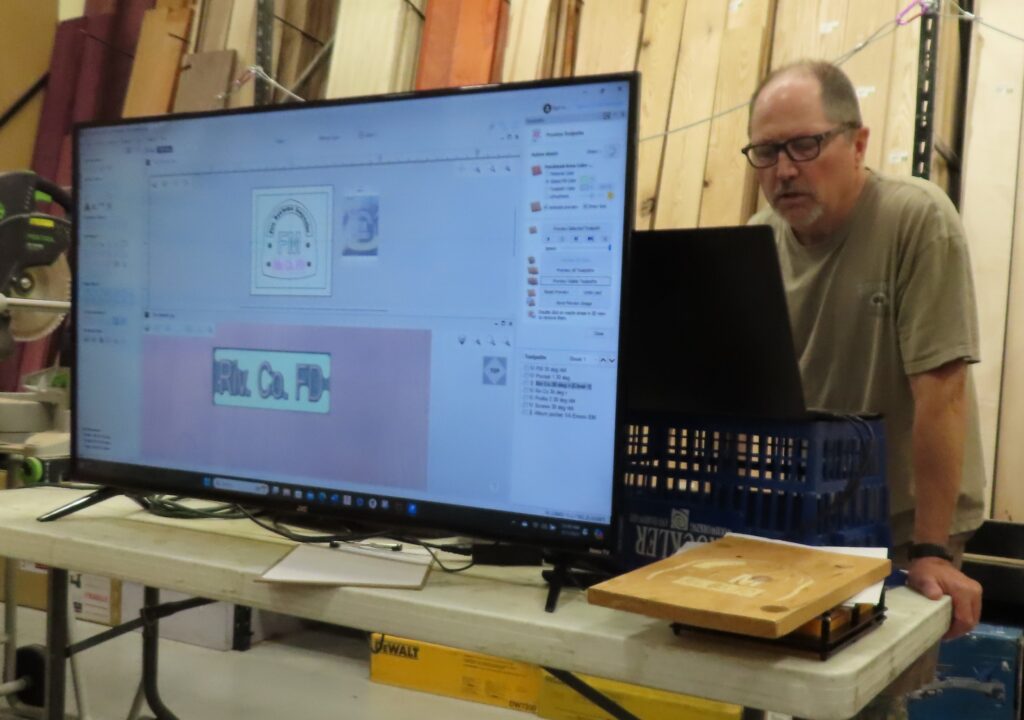

After the lesson, Matt Martel shared a project he was struggling with. Matt’s son is a firefighter (we thank him for his service). Matt is making a plaque based on the fire helmet worn by the Riverside County Fire Department. He was facing some challenges, and brought in his Vectric design.

TJ reviewed the file and noted several areas for improvement.

He presented his observations to the group, made some modifications to the file, and showed a Vectric simulation of the new machining processes:

Matt took the updates and agreed to test them and report back next month.

Show & Tell

Rick DuVall showed the completed coasters he was machining last month. He cut them from walnut using a V-bit and filled the pockets with an epoxy.

Upcoming Events

The October meeting is schedule for the 12th, and will be hosted by Tom Kaney at his shop.