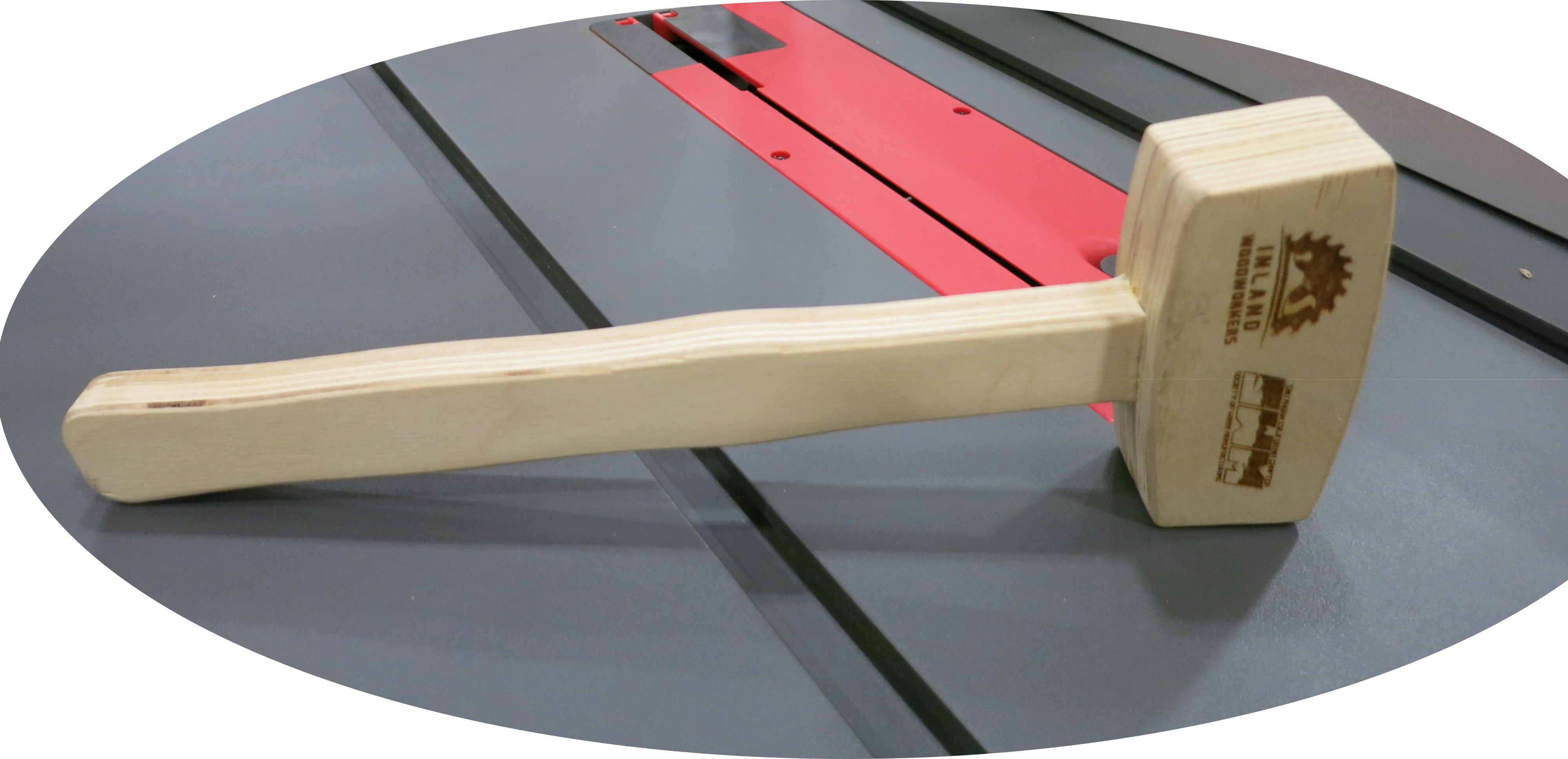

On Saturday, March 4th, the Inland Woodworkers held its monthly CNC training at the Rockler Woodworking store in Ontario. The course was led by Kenneth Thomas, and there were 14 participants. The topic of the day was making a two-sided mallet using the CNC router.

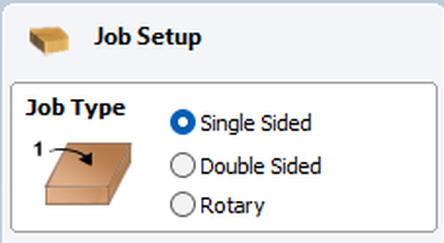

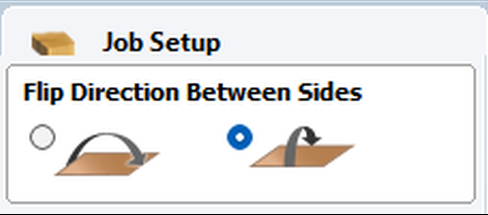

The design begins with setting the proper job parameters in Vectric, including the number of sides and the flip option. The flip option identifies the manner by which the material will be turned and aligned to machine the backside.

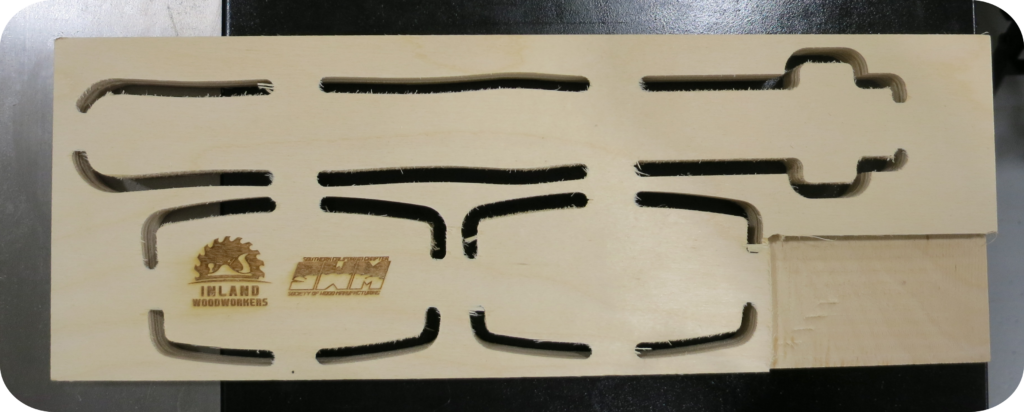

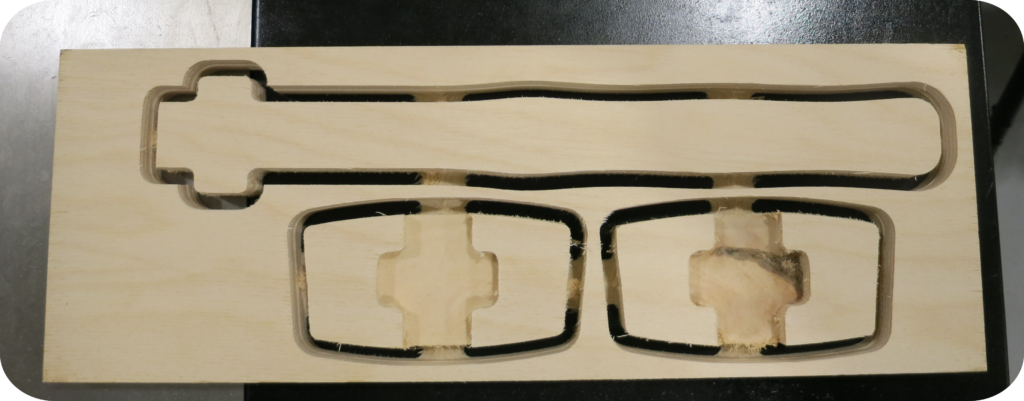

The mallet is a 2-sided project. Here is one side:

And here is the other side:

So far, so good!

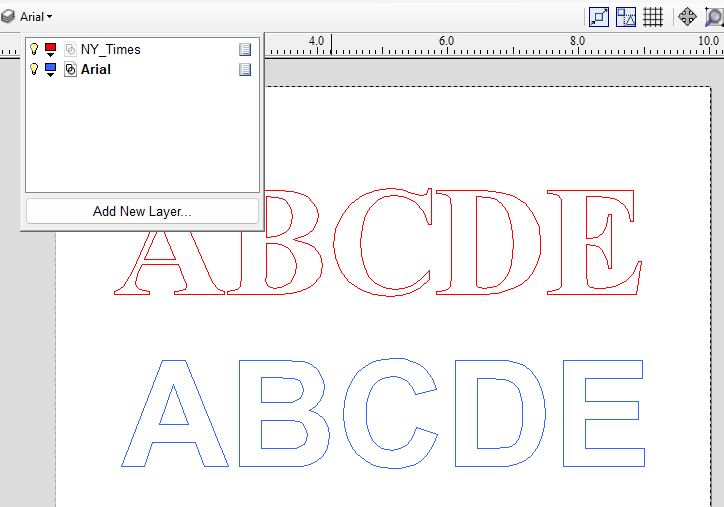

The next topic was the use of layers and how to identify parts using different colors. For the project, layers were used to separate the handle, head, and pocket. With layers, it is possible to add a component on a new layer and to make layers visible and invisible.

Here is an example of layers:

Vectric allows you to select a part, flip it, and copy it to the other side. Very handy! Kenneth also showed how to center one object within another (Vectric centers to the last object selected) using the alignment tool. Next, the participants learned how to use the Vectric inlay pocketing, profiling, and inlay tool paths for creating inlays for customizing the design.

Here is one example of customization:

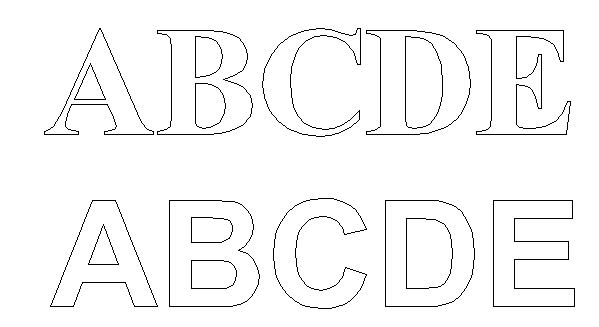

Working with fonts to tailor the mallet head can be challenging, so Kenneth gave some inside tips. Begin by selecting machinable fonts. NY Times (top line below), have font serifs (the wings) that are very difficult to reach with the router bit. Arial fonts, (bottom line below), are much easier to machine.

Using bolded fonts further improves the machinability. This is Arial Black (bolded):

Arial has sharp corners, which require rounding so that the router bit can run smoothly. Participants learned the secrets for matching the corners on both pocket and profile components.

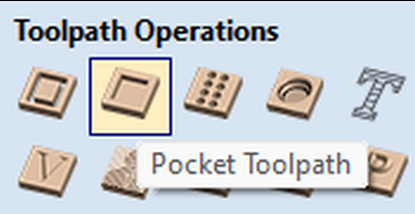

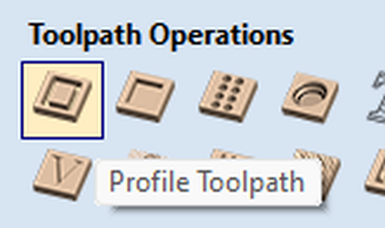

There are 2 components required for an inlay: the pocket and the profile (in this case, the letters). It is important to use offsets so that the letters will fit. It was recommended best to offset the pocket, not the letters. Start with an 0.005″ offset. Each machine has a different level of accuracy, so adjust this value based on your machine.

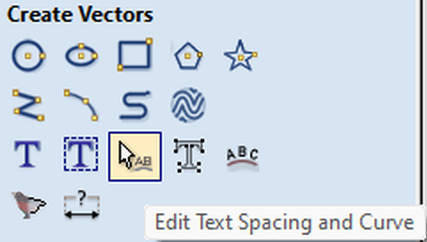

Another potential problem with fonts is spacing. If the letters are too close, the router might cut through a thin wall. Use of the Font Spacing feature will help to overcome a mishap.

With the design complete, it was time to generate some G-code and begin machining.

And there we have it, the final product!

The next training will be Saturday, April 1 at 10:00am at the Rockler Ontario store. Remember to bring your safety glasses.